Steels stainless Dàta saothrachadh tàthaidh electrode làimhe E347L-16

Iarrtas

Tha e freagarrach airson tàthadh 18% Cr-8% Ni-Nb stàilinn gun staoin (SUS347) agus 18% Cr-8% Ni-Ti stàilinn (sus321) ann an gnìomhachas peitriceimiceach, soitheach cuideam, innealan bìdh, innealan meidigeach, todhar ceimigeach agus gnìomhachasan eile.

COMPONET CEIMICEAL:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | eile | |

| RIAGHAILTEAN GB/T | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.04 | 0.03 | Cu0.75/Nb:8C-1.00 | |

| RIAGHAILTEAN AWS | 0.08 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.04 | 0.03 | Cu0.75/Nb:8C-1.00 | |

| LUACH EISIMPLEIR | 0.033 | 0.84 | 0.69 | 18.7 | 9.5 | 0.1 | 0.027 | 0.005 | Cu0.22/Nb0.50 | |

Seilbh MECANACH:

| LAOIDHEAN | neart toraidh (MPa) | Neart leudachaidh (MPa) | LUACH IMAPACT J/ ℃ | ELONGATION(%) | ||||

| RIAGHAILTEAN GB/T | - | 510 | - | 25 | ||||

| RIAGHAILTEAN AWS | - | 520 | - | 30 | ||||

| LUACH EISIMPLEIR | - | 615 | - | 36 | ||||

Paramadairean tàthaidh air am moladh:

| Sònrachaidhean trast-thomhas (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Dealain-làimhe stàilinn stainless titanium calcium, is e am prìomh cho-dhèanamh carbon ìosal 18% Cr-9% Ni-Nb; Nuair a thèid Nb a chuir ris air bunait 308, tha an susbaint gualain nas ìsle aig an aon àm, a dh ’fhaodas an aghaidh creimeadh a leasachadh gu h-èifeachdach , gu h-àraidh an intergranular corrach coileanadh.

Arc seasmhach, cumadh breagha, ripple fìnealta, frasadh beag, toirt air falbh slag furasta, deagh sheasamh teine, deagh sheasamh an aghaidh porosity.

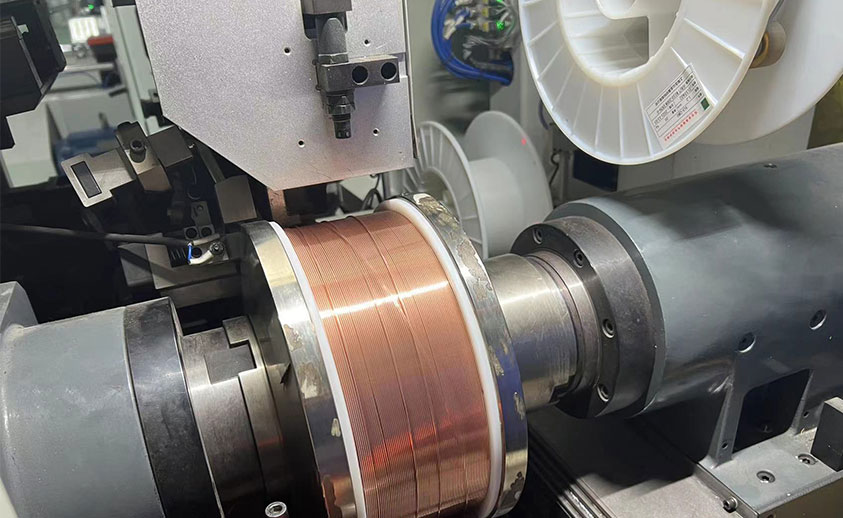

Tha Ningbo Honest Metal Materials Co, Ltd.na chompanaidh proifeasanta tàthaidh eadar-nàiseanta taobh a-staigh rannsachadh is leasachadh, cinneasachadh, reic agus riaghladh neo-eisimeileach. Chaidh a stèidheachadh ann an 2020.

Pròiseact ionad giollachd meadhanach Xinjiang Kela 2

Stuthan tàthaidh airson soithichean

Petrochemical Gansu Lanke -50 ℃ pròiseact tanca spherical propane

COMPONET CEIMICEAL:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | eile | |

| RIAGHAILTEAN GB/T | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.04 | 0.03 | Cu0.75/Nb:8C-1.00 | |

| RIAGHAILTEAN AWS | 0.08 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.04 | 0.03 | Cu0.75/Nb:8C-1.00 | |

| LUACH EISIMPLEIR | 0.033 | 0.84 | 0.69 | 18.7 | 9.5 | 0.1 | 0.027 | 0.005 | Cu0.22/Nb0.50 | |

Seilbh MECANACH:

| LAOIDHEAN | neart toraidh (MPa) | Neart leudachaidh (MPa) | LUACH IMAPACT J/ ℃ | ELONGATION(%) | ||||

| RIAGHAILTEAN GB/T | - | 510 | - | 25 | ||||

| RIAGHAILTEAN AWS | - | 520 | - | 30 | ||||

| LUACH EISIMPLEIR | - | 615 | - | 36 | ||||

Paramadairean tàthaidh air am moladh:

| Sònrachaidhean trast-thomhas (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||