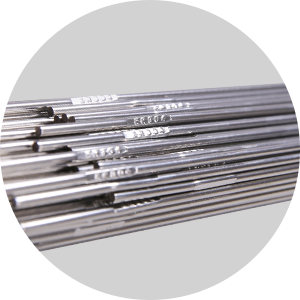

Steels stainless Leictread làimhe E410NiMo-16 Ceangal solder

Iarrtas

Freagarrach airson caitheamh bhalbhaichean nas dùbhlanaiche agus strì an aghaidh creimeadh, rotor roth-uidheam uisgeach agus tàthadh eile

Buidheann teisteanais: JIS

COMPONET CEIMICEAL:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| RIAGHAILTEAN GB/T | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 0.04 | 0.03 | 0.75 | |

| RIAGHAILTEAN AWS | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 0.04 | 0.03 | 0.75 | |

| LUACH EISIMPLEIR | 0.028 | 0.45 | 0.6 | 11.6 | 4.8 | 0.55 | 0.026 | 0.007 | 0.13 | |

Seilbh MECANACH:

| LAOIDHEAN | neart toraidh (MPa) | Neart leudachaidh (MPa) | REAMENT ℃xh | LUACH IMAPACT J/ ℃ | ELONGATION(%) | ||||||

| RIAGHAILTEAN GB/T | - | 760 | 595-620x1 | - | 10 | ||||||

| RIAGHAILTEAN AWS | - | 760 | 595-620x1 | - | 15 | ||||||

| LUACH EISIMPLEIR | - | 925 | 620x1 | - | 17 | ||||||

Paramadairean tàthaidh air am moladh:

| Sònrachaidhean trast-thomhas (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||

Dealain stàilinn stainless titanium-calcium martensitic, is e am prìomh cho-dhèanamh 11.5% Cr-4.5% Ni-0.55% Mo;

Mar thoradh air co-phàirt alloy NiMo a chuir ris, tha an aghaidh creimeadh nas seasmhaiche, tha an cruas agus an aghaidh caitheamh teòthachd àrd air a leasachadh, agus tha an sgàineadh fuar air a chasg gu h-èifeachdach. Tha cruas an tàthaidh timcheall air 270HB.

Arc seasmhach, cumadh breagha, ripple fìnealta, frasadh beag, toirt air falbh slag furasta, deagh sheasamh teine, deagh sheasamh an aghaidh porosity.

Tha Ningbo Honest Metal Materials Co, Ltd.na chompanaidh proifeasanta tàthaidh eadar-nàiseanta taobh a-staigh rannsachadh is leasachadh, cinneasachadh, reic agus riaghladh neo-eisimeileach. Chaidh a stèidheachadh ann an 2020.

9,000 tonna de cheimigean

Zhejiang Petrochemical 40 millean tunna / bliadhna fùirneis pròiseact amalachadh

Zhangjiagang Hanzhong Cryogenic Technology Co., LTD. Uidheam stòraidh agus còmhdhail aig teòthachd ìosal

COMPONET CEIMICEAL:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| RIAGHAILTEAN GB/T | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 0.04 | 0.03 | 0.75 | |

| RIAGHAILTEAN AWS | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 0.04 | 0.03 | 0.75 | |

| LUACH EISIMPLEIR | 0.028 | 0.45 | 0.6 | 11.6 | 4.8 | 0.55 | 0.026 | 0.007 | 0.13 | |

Seilbh MECANACH:

| LAOIDHEAN | neart toraidh (MPa) | Neart leudachaidh (MPa) | REAMENT ℃xh | LUACH IMAPACT J/ ℃ | ELONGATION(%) | ||||||

| RIAGHAILTEAN GB/T | - | 760 | 595-620 × 1 | - | 10 | ||||||

| RIAGHAILTEAN AWS | - | 760 | 595-620 × 1 | - | 15 | ||||||

| LUACH EISIMPLEIR | - | 925 | 620 × 1 | - | 17 | ||||||

Paramadairean tàthaidh air am moladh:

| Sònrachaidhean trast-thomhas (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||